Rotary Heat Exchangers

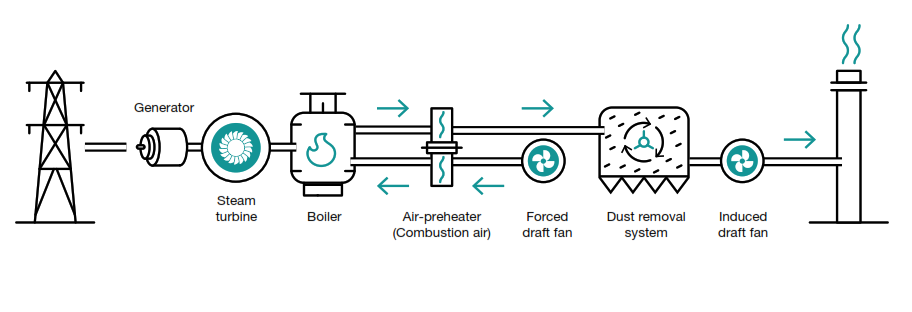

Howden gas gas heaters and air preheaters recover heat that would otherwise be wasted, playing a vital role increasing energy efficiency across a range of industrial processes.

Howden has been at the forefront of improving efficiency in boiler-based power plants and industries with fired heaters since the emergence of the technology over a hundred years ago. As early as the 1930's, the heater was applied to FGD systems and since then to SCR systems to optimise emission controls.

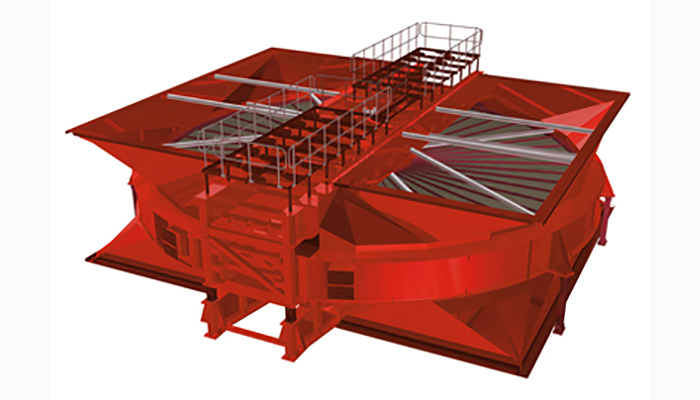

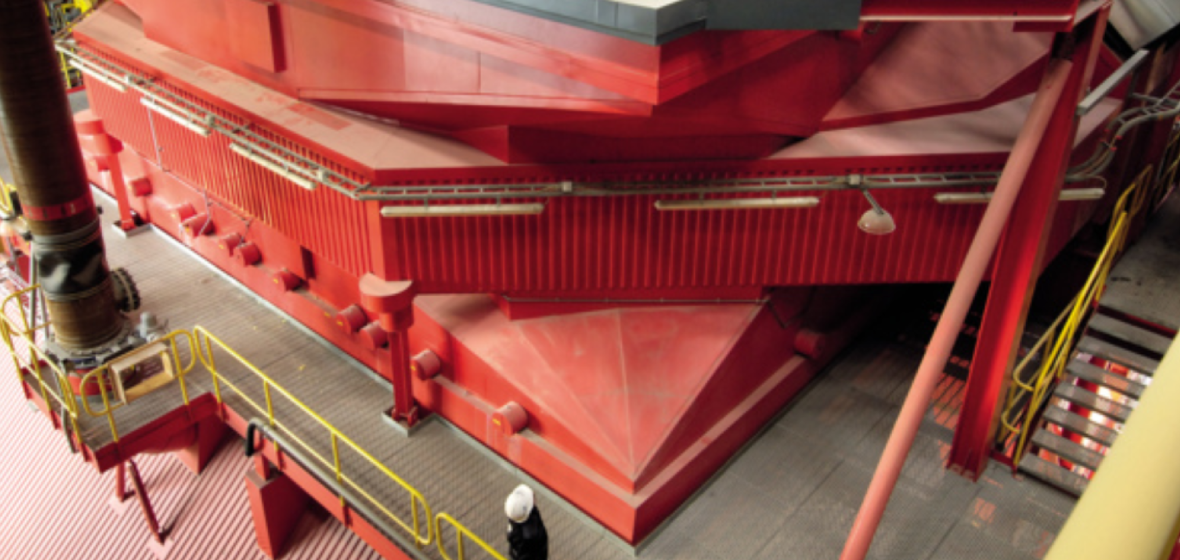

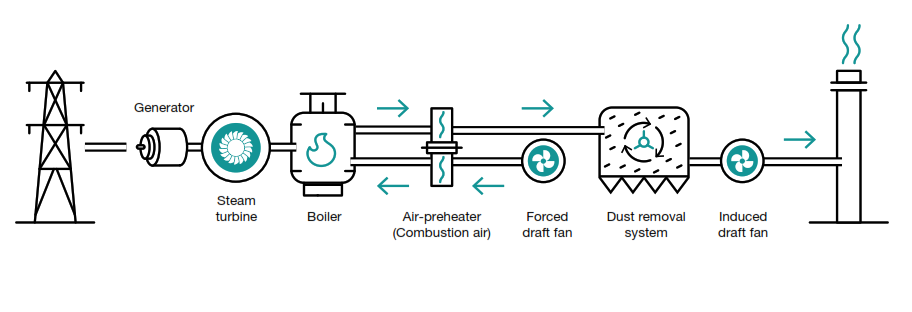

Regenerative air preheaters extract the waste heat from the exhaust gas as it leaves the furnace and transfers this energy to the inlet air used in the furnace to provide the oxygen to fire the fuel.

As the preheater slowly rotates at around 1-2 rpm, thin metal heat transfer elements absorb heat from the hot gas stream and transfer it to the incoming cold air stream.

Aim: to increase the efficiency of the boiler, furnace or fired heater by 10-15%.

Typical processes served

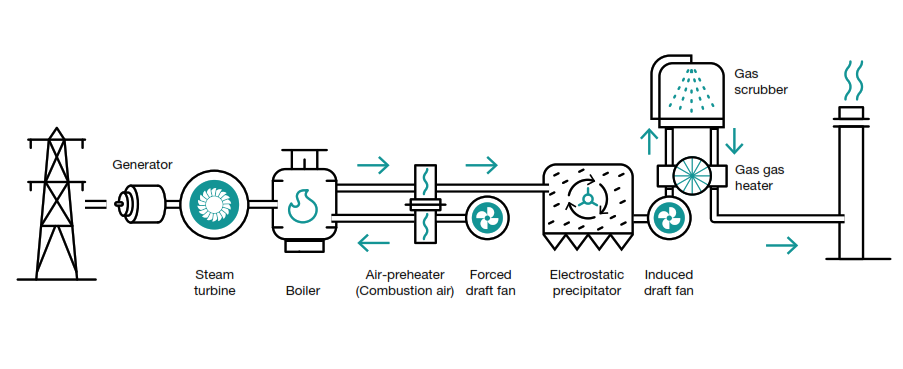

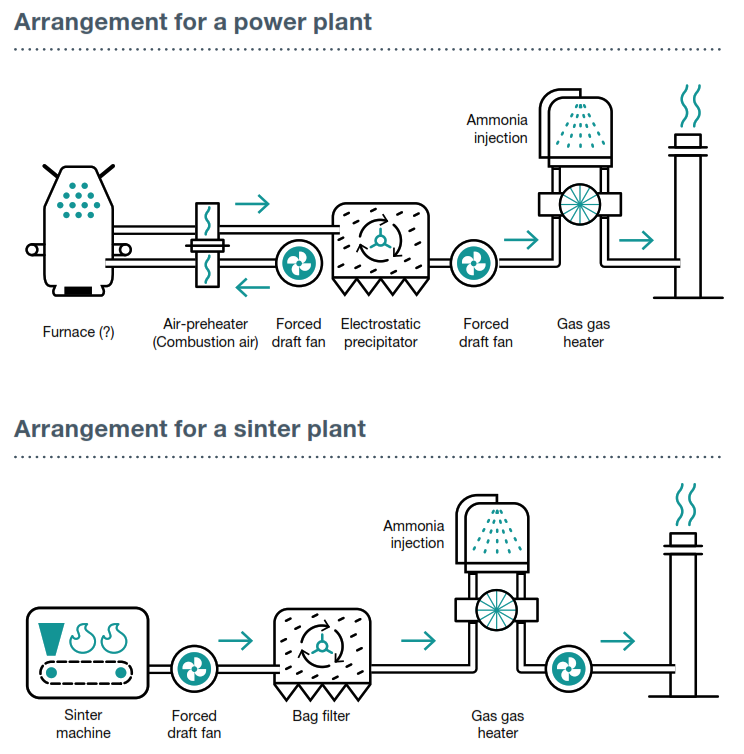

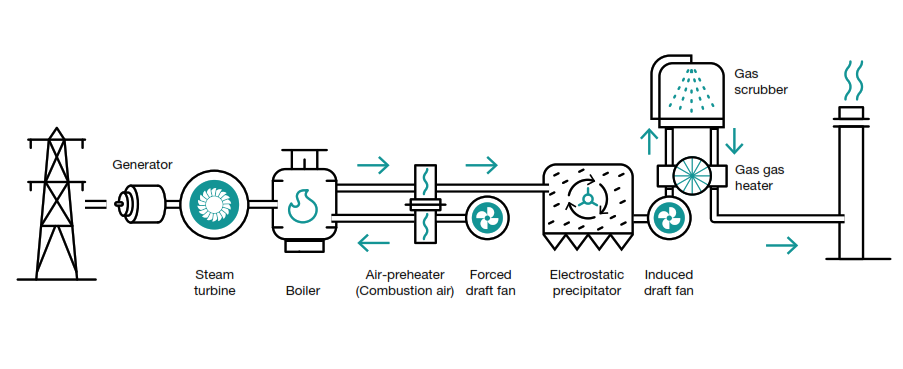

Sulphur dioxide is a harmful acidic gas emitted as part of fossil fuel combustion. As Flue Gas Desulphurisation (FGD) technology was introduced to control emissions by scrubbing the gas, the rotary heater found another valuable application.

Many FGD systems are designed with gas reheaters (GGH) to reduce the flue gas temperature before the adsorber and reheat the treated gas producing a ‘dry’ stack. This ensures sufficient plume buoyancy and prevents ground level SO2 concentrations rising above specified limits.

The GGH reduces water usage in the adsorber and eliminates stack liquid discharge. It also avoids high stack renovation costs and maintenance issues caused by acid corrosion and drain blockage.

Regenerative gas/gas heaters recover energy from the untreated gas as it enters the FGD scrubber by absorbing the waste heat in thin metal heat transfer elements. The elements typically rotate at around 0.5-1 rpm to transfer the heat to the treated gas being sent to the stack.

Aim: to aid SOX treatment process and reduce costs by reheating treated gas to required buoyancy level.

Typical processes served

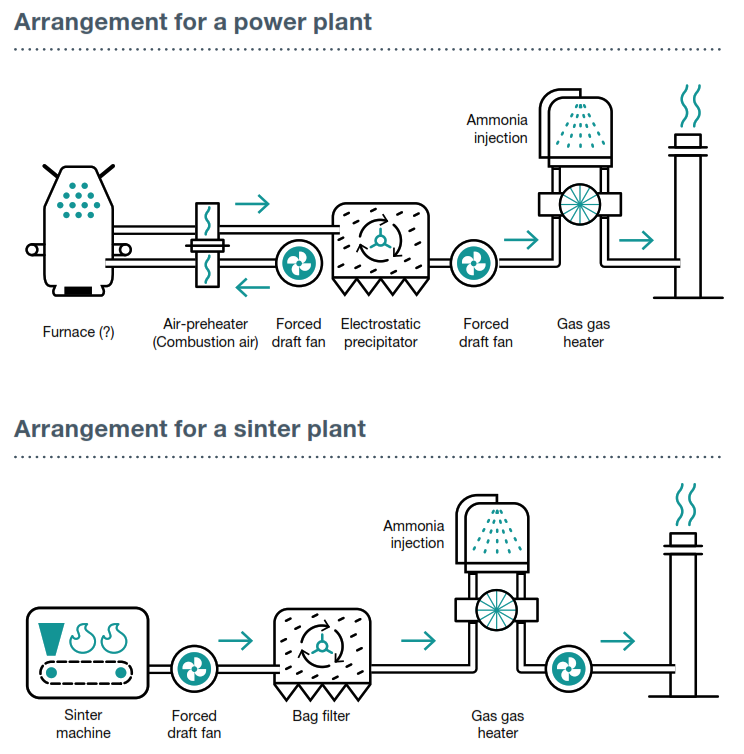

Nitric oxide is a harmful gas emitted as part of fossil fuel combustion. As Selective Catalytic Reduction (SCR) technology was introduced to control emissions, the rotary heater found another valuable application.

Within some plants, where the SCR cannot be fitted at the economiser, the low dust (or tail end) SCR arrangement is used to reduce the NOx emissions.

Regenerative gas/gas heaters (GGH) recover energy from the treated gas as it leaves the SCR by absorbing the waste heat in thin metal heat transfer elements. In this application, the heated elements rotate at between 0.6-1 rpm to transfer the heat to the untreated gas feed thereby reducing the level of additional heating required to reach the reaction temperature.

Aim: to increase the efficiency of the NOX emissions system by reducing additional heating required to reach the reaction temperature for the destruction of NOX (≈ 250 - 330oC).

Typical processes served

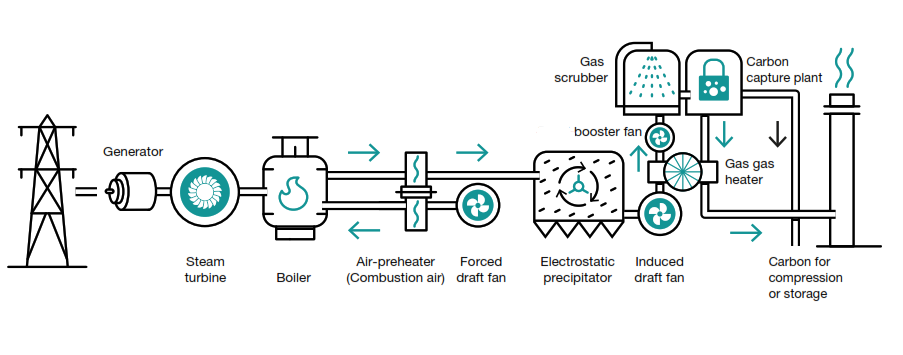

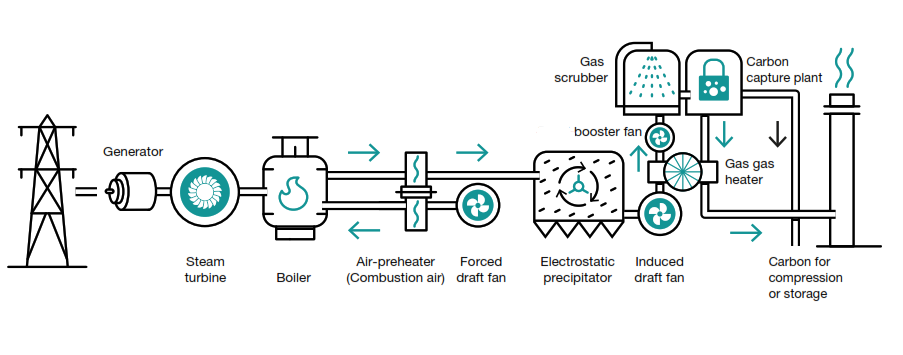

As industry moves towards carbon capture and storage, rotary heater technology is being integrated into developing solutions.

Post Combustion Carbon Capture (PCC) plants can be developed as part of a new power plant or retrofitted. They capture the carbon dioxide (CO2) in the flue gasfor use as a product or storage in permanent underground geological storage facilities.

The heater for this process is similar to the gas gas heater (GGH) with similar temperatures to the FGD process. The heater combines cooling the flue gas prior to the FGD plant and re-heating the treated gas after the carbon capture plant for exhaust to the stack.

Aim: to lower the temperature of the untreated gas before the capture plant and use this to re-heat the treated gas to reduce plume visibility and have enough buoyancy to exit the chimney.

Applicable products

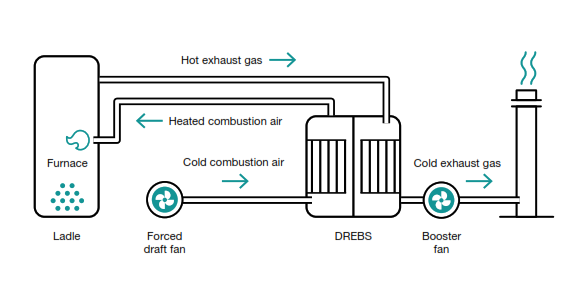

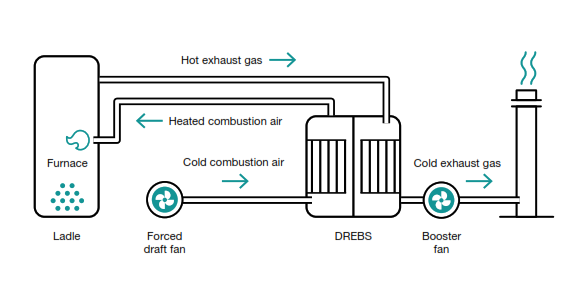

Many industrial industrial processes involve high temperature firing. These processes are high consumers of energy, and so any means of reducing requirements can add up to substantial operating savings.

Howden's solution comes from our Rothemühle brand and their DREBS heater. This is a rotating regenerator burner system, where the heater absorbs energy from high temperature exhaust gas on ceramic heating surfaces, which then rotate to transfer heat into the air flow.

Compared to conventional recuperators, the DREBS can be used for significantly higher temperatures of up to 1200oC. Due to the high thermal efficiency of >85%, energy savings can be doubled compared to conventional recuperators.

Aim: to increase the efficiency of burners and dryers by up to 100% over conventional recuperators.

Typical applications

Regenerative air preheaters extract the waste heat from the exhaust gas as it leaves the furnace and transfers this energy to the inlet air used in the furnace to provide the oxygen to fire the fuel.

As the preheater slowly rotates at around 1-2 rpm, thin metal heat transfer elements absorb heat from the hot gas stream and transfer it to the incoming cold air stream.

Aim: to increase the efficiency of the boiler, furnace or fired heater by 10-15%.

Typical processes served

Sulphur dioxide is a harmful acidic gas emitted as part of fossil fuel combustion. As Flue Gas Desulphurisation (FGD) technology was introduced to control emissions by scrubbing the gas, the rotary heater found another valuable application.

Many FGD systems are designed with gas reheaters (GGH) to reduce the flue gas temperature before the adsorber and reheat the treated gas producing a ‘dry’ stack. This ensures sufficient plume buoyancy and prevents ground level SO2 concentrations rising above specified limits.

The GGH reduces water usage in the adsorber and eliminates stack liquid discharge. It also avoids high stack renovation costs and maintenance issues caused by acid corrosion and drain blockage.

Regenerative gas/gas heaters recover energy from the untreated gas as it enters the FGD scrubber by absorbing the waste heat in thin metal heat transfer elements. The elements typically rotate at around 0.5-1 rpm to transfer the heat to the treated gas being sent to the stack.

Aim: to aid SOX treatment process and reduce costs by reheating treated gas to required buoyancy level.

Typical processes served

Nitric oxide is a harmful gas emitted as part of fossil fuel combustion. As Selective Catalytic Reduction (SCR) technology was introduced to control emissions, the rotary heater found another valuable application.

Within some plants, where the SCR cannot be fitted at the economiser, the low dust (or tail end) SCR arrangement is used to reduce the NOx emissions.

Regenerative gas/gas heaters (GGH) recover energy from the treated gas as it leaves the SCR by absorbing the waste heat in thin metal heat transfer elements. In this application, the heated elements rotate at between 0.6-1 rpm to transfer the heat to the untreated gas feed thereby reducing the level of additional heating required to reach the reaction temperature.

Aim: to increase the efficiency of the NOX emissions system by reducing additional heating required to reach the reaction temperature for the destruction of NOX (≈ 250 - 330oC).

Typical processes served

As industry moves towards carbon capture and storage, rotary heater technology is being integrated into developing solutions.

Post Combustion Carbon Capture (PCC) plants can be developed as part of a new power plant or retrofitted. They capture the carbon dioxide (CO2) in the flue gasfor use as a product or storage in permanent underground geological storage facilities.

The heater for this process is similar to the gas gas heater (GGH) with similar temperatures to the FGD process. The heater combines cooling the flue gas prior to the FGD plant and re-heating the treated gas after the carbon capture plant for exhaust to the stack.

Aim: to lower the temperature of the untreated gas before the capture plant and use this to re-heat the treated gas to reduce plume visibility and have enough buoyancy to exit the chimney.

Applicable products

Many industrial industrial processes involve high temperature firing. These processes are high consumers of energy, and so any means of reducing requirements can add up to substantial operating savings.

Howden's solution comes from our Rothemühle brand and their DREBS heater. This is a rotating regenerator burner system, where the heater absorbs energy from high temperature exhaust gas on ceramic heating surfaces, which then rotate to transfer heat into the air flow.

Compared to conventional recuperators, the DREBS can be used for significantly higher temperatures of up to 1200oC. Due to the high thermal efficiency of >85%, energy savings can be doubled compared to conventional recuperators.

Aim: to increase the efficiency of burners and dryers by up to 100% over conventional recuperators.

Typical applications

Howden has been involved with rotary regenerative heaters since first forming a joint venture with Fredrik Ljungström, the inventor, in 1923. The Rothemühle brand was added in 2021, bringing with it almost 90 years of heater experience.

Our capabilities stretch from ensuring our large global base of heaters continue to perform for our customers to adapting the technology for emerging industrial needs.

Our heaters operate in continuous service with limited service intervals required. To maintain them at optimal performance, though we have a global team of engineers ready to provide maintenance for all rotary heat exchangers with our own brands being Howden, Sirocco, Tallares Sanchez Luengo (TSL) and Rothemühle (including LUGAT).

As plant duty conditions can change over the years, we offer a range of engineering services to assess and implement performance improvements and life extensions.

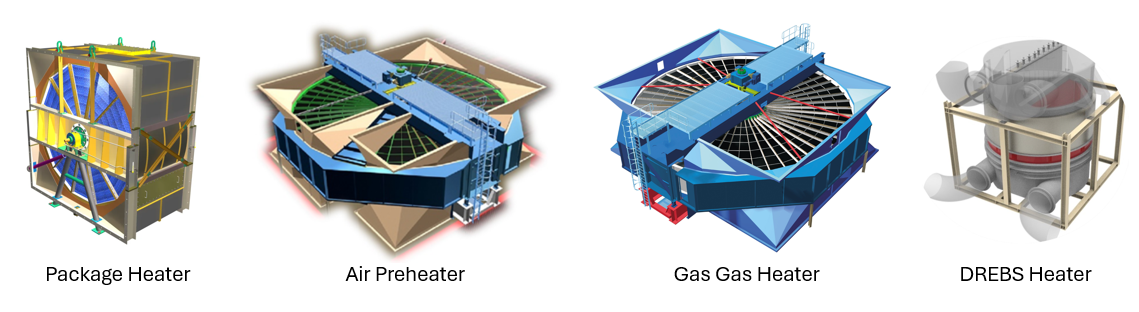

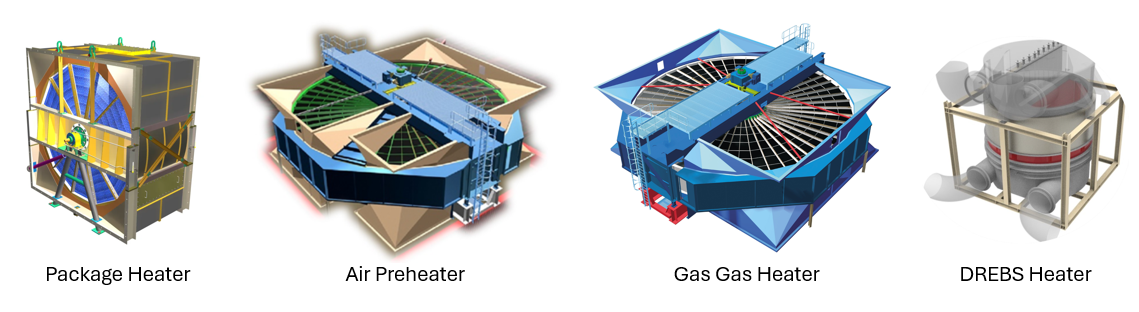

Howden heaters operate across a wide range of gas volumes, temperatures and footprints to align with the requirements of multiple processes and engineering configurations.

| Product | Thermal Energy Recovery | Gas Volume | Gas Temperature | Footprint | Leakage | Applications |

|---|---|---|---|---|---|---|

| Package Heater | up to 15MW | 45 to 200 tonnes/h | up to 370oC (698oF) | approx. 3.5m2 to 5.4m2 | <5% Using single/double radial and double axial seals | Smaller scale air preheating |

| Air Preheater | up to 100MW | 200 to 3600 tonnes/h | up to 500oC (932oF) | up to 625m2 | <5% Using labyrinth multiple seals with optional sectors plates | Large volume air preheating |

| Gas Gas Heater | up to 100MW | 200 to 3600 tonnes/h | up to 500oC (932oF) | up to 625m2 | <0.5% Using labyrinth multiple seals, purge and scavenge systems with optional sectors plates | Gas reheating for FGD and gas preheating for SCR |

| DREBS Heater | up to 7MW | up to 40 tonnes/h | up to 1200oC (2192oF) | up to 16m2 | Variable based on pressure and application | High temperature energy recovery for metals, glass and oven applications |

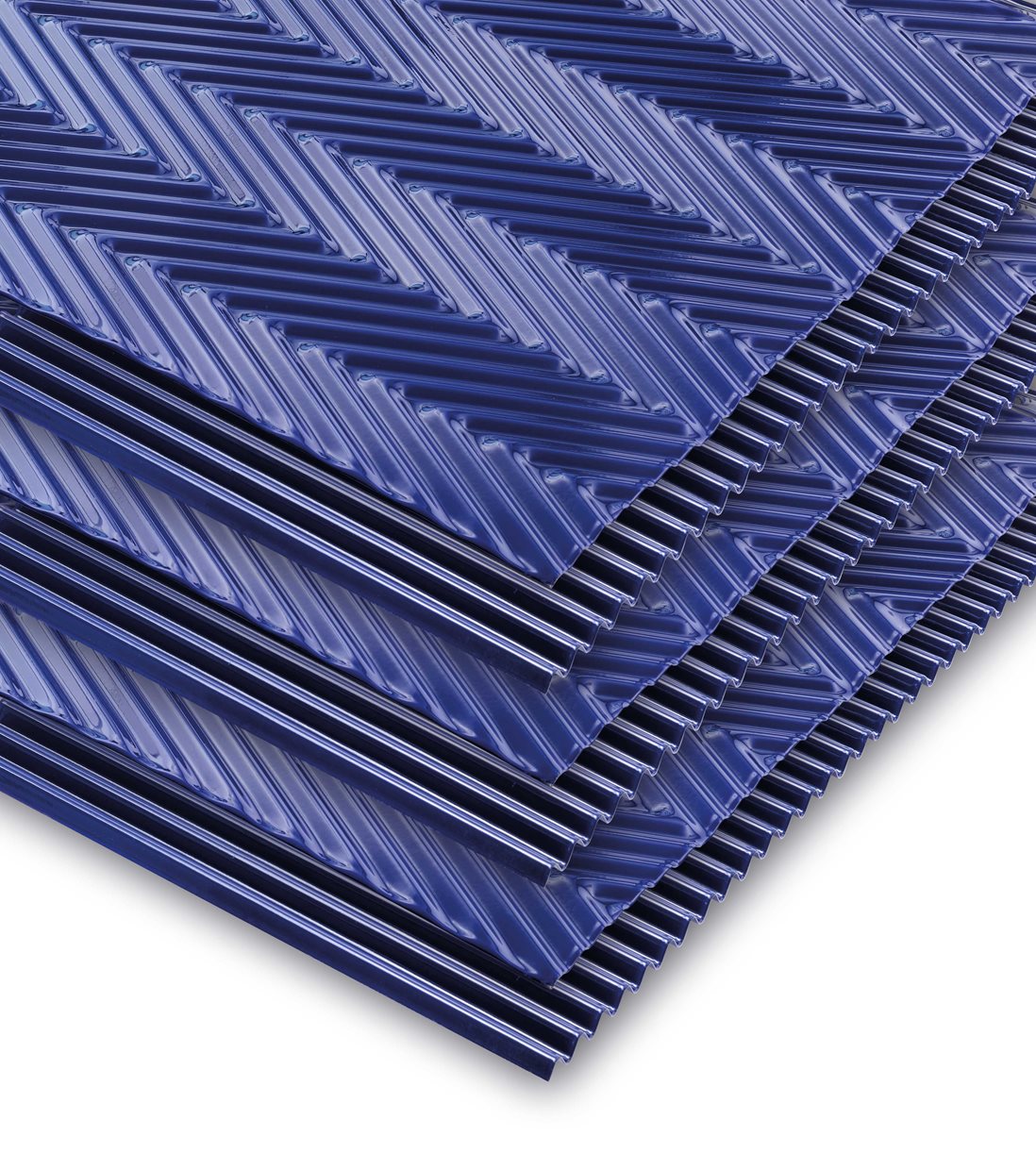

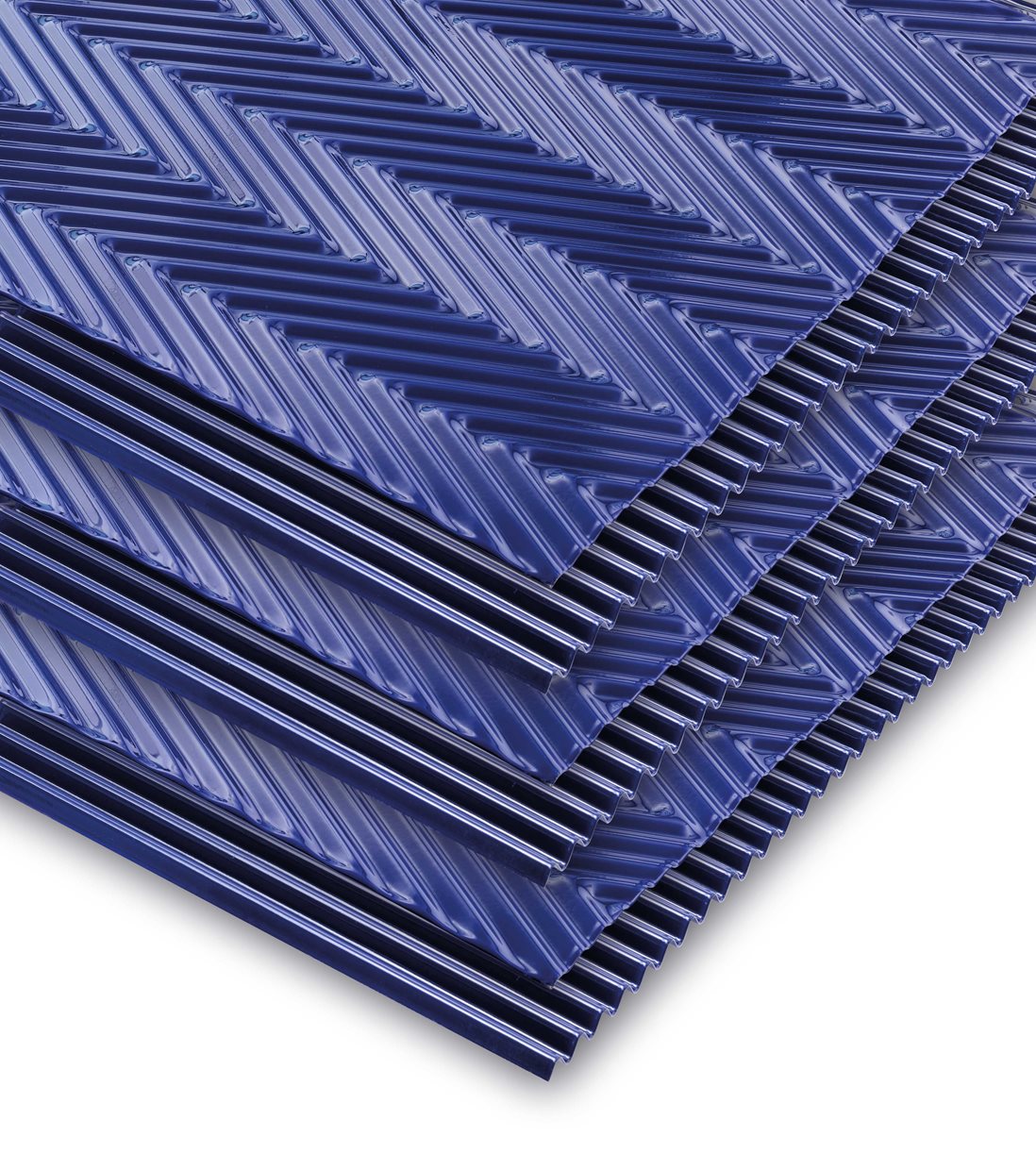

Keeping maximum efficiency requires an in-depth knowledge of how the heater will perform over time with each particular fuel type. The heat transfer elements are designed specifically for each application and fuel.

Our wide range of profiles, enables us to offer the right balance of thermodynamic performance, pressure drop and ease of cleaning for any situation. These profiles can be chosen from our range (which includes the world's first commercially available dual-profile element), or we can match existing profiles that you have already.

We are the world's leader when it comes to producing enamelled elements, which offer a combination of both corrosion protection and good cleanliness when used in rigorous environments.

Elements play a critical role in heater performance, but by taking a systematic view of the science of the contamination and cleaning cycle, we have evolved an integrated system that delivers far more than the sum of its parts:

SureCoat™ (high performance enamelling) + SurePack™ (optimised element packaging) + Enerjet™ (advanced cleaning system).

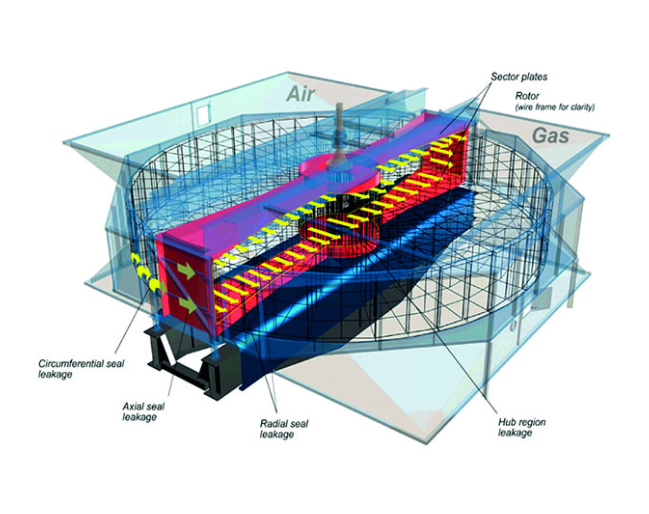

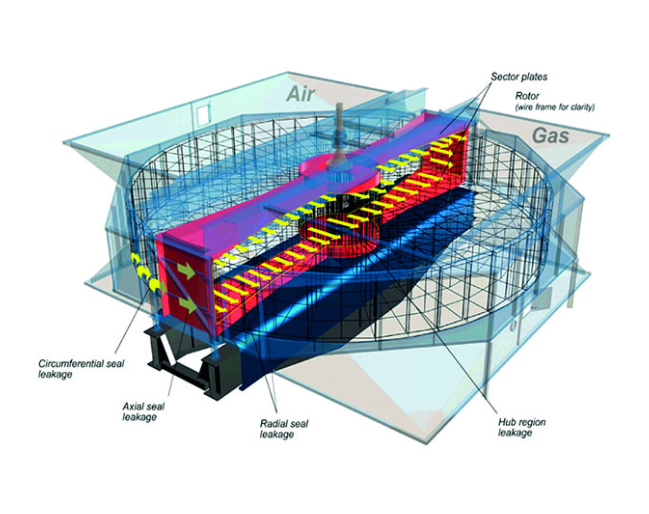

Minimising gas leakage is a key consideration and Howden has developed a series of innovative solutions.

The VN sealing system maintains consistently low leakage for extended periods. Additional methods are adopted for GGHs such pressurising the seal space with clean gas, using a purge fan to create a slight pressure difference. A scavenge system then expels dirty gas from the elements using treated gas.

Contact SealsFlexible contact seals for rotary heat exchangers are a method of minimising the direct leakage gaps between the hot end of the rotor and the sectorplates, which separate the air and gas flows.

Standard seals fail due to constant flexing, therefore Howden carried out an extensive development programme to optimise contact seals for suitable applications providing major leakage reductions. As the seals work best in situations where gaps are small and even, leakage reduction can be enhanced further by combining with parabolic sectorplates.

Parabolic SectorplatesIncreased environmental scrutiny and demand for the highest levels of efficiency have driven Howden to develop parabolic sectorplates (patent pending) for use with our heaters.

Hot End Sectorplates are designed with variable stiffness to deform parabolically, when actuated, to match the shape of the deformed operating rotor. This minimises the hot end leakage gap.

Howden parabolic sectorplates not only reduce draft fan power in the plant, but also reduce the gas mass flow to downstream emissions reduction equipment.

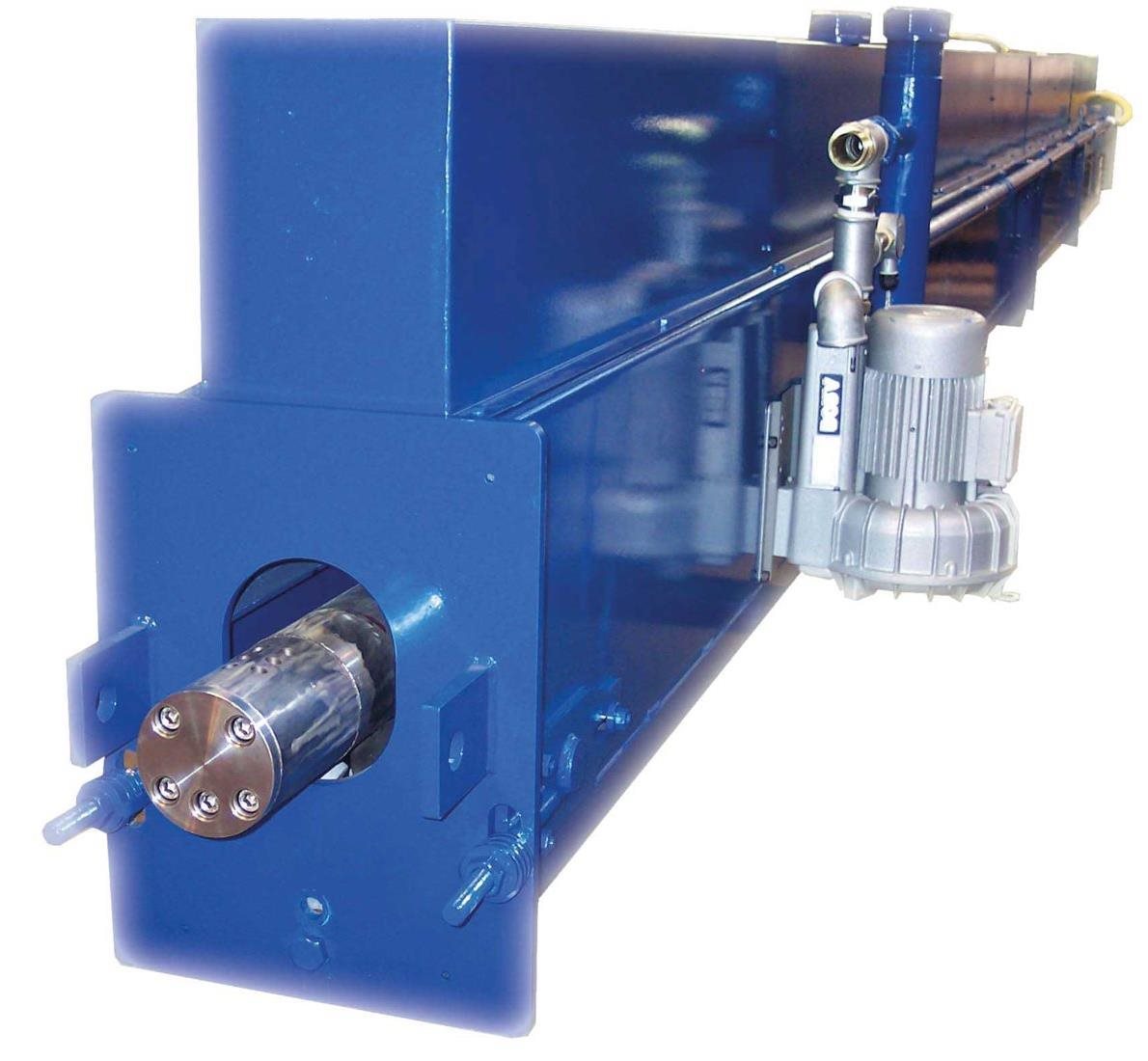

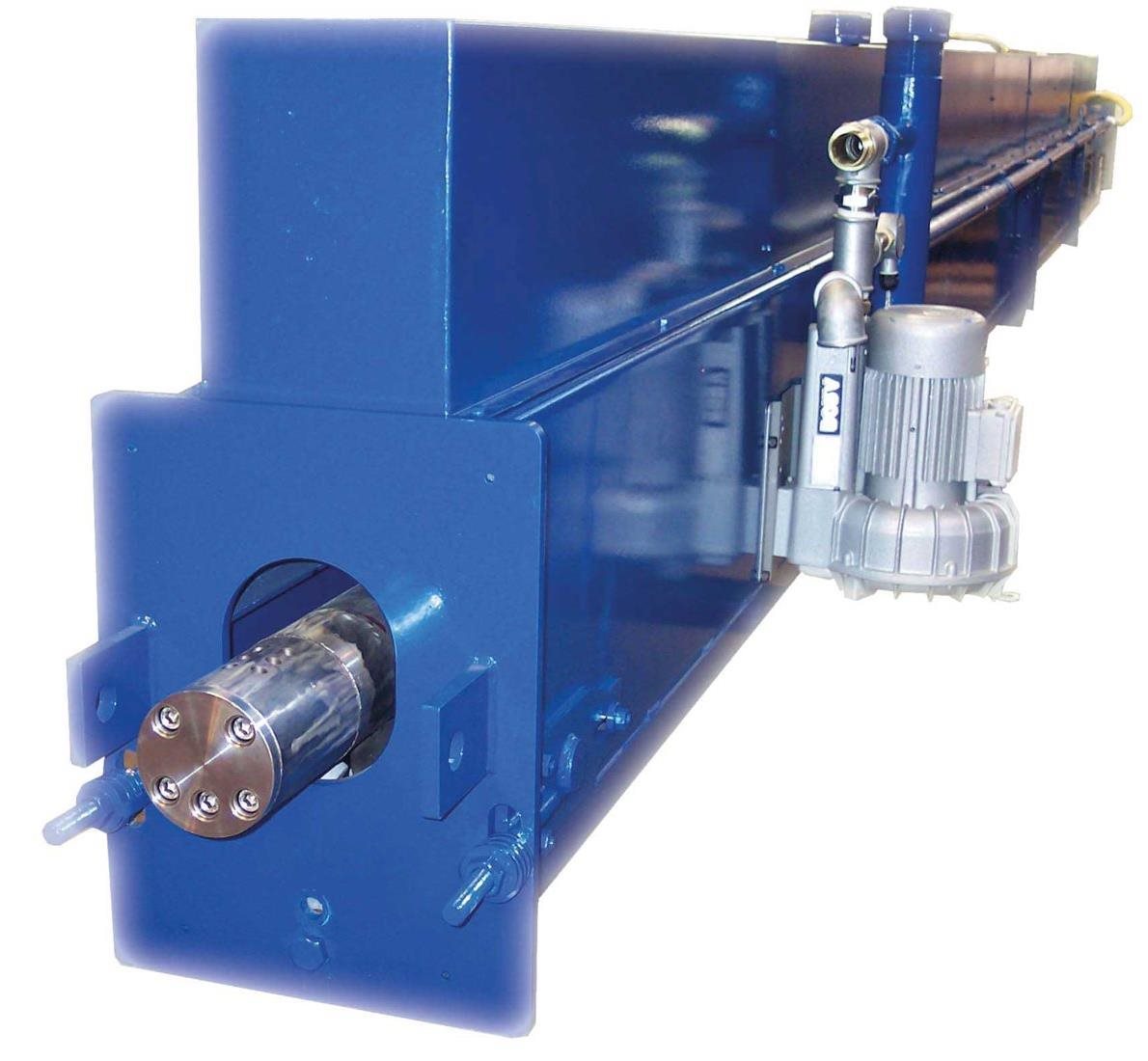

Unlike tubular or plate recuperative heat exchangers, fouling does not cause deterioration in heat transfer in rotary regenerative heat exchangers. Fouling increases pressure differentials and consequently fan power and leakage. Keeping the elements clean though, maintains high availability and minimizes maintenance needs to scheduled services.

The Howden Enerjet™ cleaning system is a method of on-line high-pressure water washing of air preheaters, designed to provide effective and efficient cleaning of severely fouled heat exchanger elements while the air preheater is in normal use.

The Enerjet™ system can be used with any type of air preheater from any manufacturer, and works well with most kinds of element profile.

Enerjet™ combined with SureCoat™ (high performance enamelled elements) and SurePack™ (optimised element packaging) provides a systematic approach to the contamination and cleaning cycle delivering more than the sum of its parts.

Howden heaters operate across a wide range of gas volumes, temperatures and footprints to align with the requirements of multiple processes and engineering configurations.

| Product | Thermal Energy Recovery | Gas Volume | Gas Temperature | Footprint | Leakage | Applications |

|---|---|---|---|---|---|---|

| Package Heater | up to 15MW | 45 to 200 tonnes/h | up to 370oC (698oF) | approx. 3.5m2 to 5.4m2 | <5% Using single/double radial and double axial seals | Smaller scale air preheating |

| Air Preheater | up to 100MW | 200 to 3600 tonnes/h | up to 500oC (932oF) | up to 625m2 | <5% Using labyrinth multiple seals with optional sectors plates | Large volume air preheating |

| Gas Gas Heater | up to 100MW | 200 to 3600 tonnes/h | up to 500oC (932oF) | up to 625m2 | <0.5% Using labyrinth multiple seals, purge and scavenge systems with optional sectors plates | Gas reheating for FGD and gas preheating for SCR |

| DREBS Heater | up to 7MW | up to 40 tonnes/h | up to 1200oC (2192oF) | up to 16m2 | Variable based on pressure and application | High temperature energy recovery for metals, glass and oven applications |

Keeping maximum efficiency requires an in-depth knowledge of how the heater will perform over time with each particular fuel type. The heat transfer elements are designed specifically for each application and fuel.

Our wide range of profiles, enables us to offer the right balance of thermodynamic performance, pressure drop and ease of cleaning for any situation. These profiles can be chosen from our range (which includes the world's first commercially available dual-profile element), or we can match existing profiles that you have already.

We are the world's leader when it comes to producing enamelled elements, which offer a combination of both corrosion protection and good cleanliness when used in rigorous environments.

Elements play a critical role in heater performance, but by taking a systematic view of the science of the contamination and cleaning cycle, we have evolved an integrated system that delivers far more than the sum of its parts:

SureCoat™ (high performance enamelling) + SurePack™ (optimised element packaging) + Enerjet™ (advanced cleaning system).

Minimising gas leakage is a key consideration and Howden has developed a series of innovative solutions.

The VN sealing system maintains consistently low leakage for extended periods. Additional methods are adopted for GGHs such pressurising the seal space with clean gas, using a purge fan to create a slight pressure difference. A scavenge system then expels dirty gas from the elements using treated gas.

Contact SealsFlexible contact seals for rotary heat exchangers are a method of minimising the direct leakage gaps between the hot end of the rotor and the sectorplates, which separate the air and gas flows.

Standard seals fail due to constant flexing, therefore Howden carried out an extensive development programme to optimise contact seals for suitable applications providing major leakage reductions. As the seals work best in situations where gaps are small and even, leakage reduction can be enhanced further by combining with parabolic sectorplates.

Parabolic SectorplatesIncreased environmental scrutiny and demand for the highest levels of efficiency have driven Howden to develop parabolic sectorplates (patent pending) for use with our heaters.

Hot End Sectorplates are designed with variable stiffness to deform parabolically, when actuated, to match the shape of the deformed operating rotor. This minimises the hot end leakage gap.

Howden parabolic sectorplates not only reduce draft fan power in the plant, but also reduce the gas mass flow to downstream emissions reduction equipment.

Unlike tubular or plate recuperative heat exchangers, fouling does not cause deterioration in heat transfer in rotary regenerative heat exchangers. Fouling increases pressure differentials and consequently fan power and leakage. Keeping the elements clean though, maintains high availability and minimizes maintenance needs to scheduled services.

The Howden Enerjet™ cleaning system is a method of on-line high-pressure water washing of air preheaters, designed to provide effective and efficient cleaning of severely fouled heat exchanger elements while the air preheater is in normal use.

The Enerjet™ system can be used with any type of air preheater from any manufacturer, and works well with most kinds of element profile.

Enerjet™ combined with SureCoat™ (high performance enamelled elements) and SurePack™ (optimised element packaging) provides a systematic approach to the contamination and cleaning cycle delivering more than the sum of its parts.

Download available marketing literature

Head Office +44 141 885 7500

Package Heaters +34 968 32 00 64